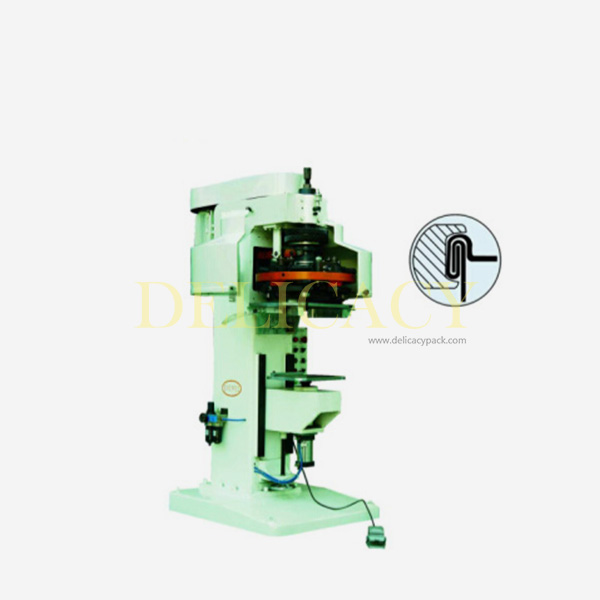

Multi-functional Seaming Machine For Can Making Machine

This machine is used for seaming operation of different types of round/rectangular/square/irregular can bodies by tooling changeover.

This machine is used for seaming operation of different types of round/rectangular/square/irregular can bodies by tooling changeover.

Applicable can size range:1-25L round/rectangular/square/irregular cans

Applicable material thickness:0.18-0.32mm

Production capacity:10-20CPM

Main axle rotation speed: 130rpm

Motor power:2.2Kw

Voltage:AC 380V 50HZ

Dimension:1070X720X2050mm

Weight:960kg

A Multi-functional Seaming Machine for Can Making Machine is a specialized equipment used in the can manufacturing process, specifically designed for seaming and closing the lids of cans. The machine is an essential part of the can manufacturing process, where it is used to ensure that the lids of cans are securely sealed.

The machine works by feeding the lid and can body through the seaming rollers, which press and crimp the lid onto the can body. The machine is programmed to work with different sizes and shapes of lids and can bodies, and can produce a variety of seamed cans.

The Multi-functional Seaming Machine for Can Making Machine is an important piece of equipment in the can manufacturing industry, particularly in industries that require the production of cans with different sizes and shapes in large quantities. The machine can be used to seam and close lids of cans used for storing a variety of products, including food, beverages, and even chemicals.

The accuracy and consistency of the Multi-functional Seaming Machine for Can Making Machine are essential in ensuring that the cans produced are of high quality and can effectively preserve and protect their contents. The machine helps to improve the efficiency and effectiveness of the can manufacturing process, ensuring that the lids of cans are securely sealed and meet the required standards and specifications.

Overall, the Multi-functional Seaming Machine for Can Making Machine is an important piece of equipment in the can manufacturing process. It helps to improve the quality and consistency of the cans produced, ensuring that they are of high quality and can effectively preserveand protect their contents. The machine’s ability to work with different sizes and shapes of lids and can bodies, and its multi-functional capabilities make it a valuable asset in the can manufacturing industry. It helps to reduce labor costs and increase production efficiency, ultimately leading to a more efficient and cost-effective can manufacturing process.