conical pail bottom and cover fully auto machinery line

60epm D271mm Bottom Lid Line for Tin Pail Can makingTechnical flow:Auto feeding device-Blank and form- Turn and conveyor-Stacking.Curling-Lining-Drying-Stacking-Output60epm Curled Lug Lid Line D282mm with EVA Gasket installed for Steel Pail CanMaking

Technical flow:Auto feeding device-Blank and form- Stacking-2nd press for finalforming-Turn and conveyor-3nd pressing for final forming-Glue strip-Output60epm Lug Lid Line D282mm with EVA Gasket installed for Steel Pail Can MakingTechnical flow:Auto feeding device-Blank and form- Stacking-2nd press for finalforming-Turn and conveyor-Glue strip-Output

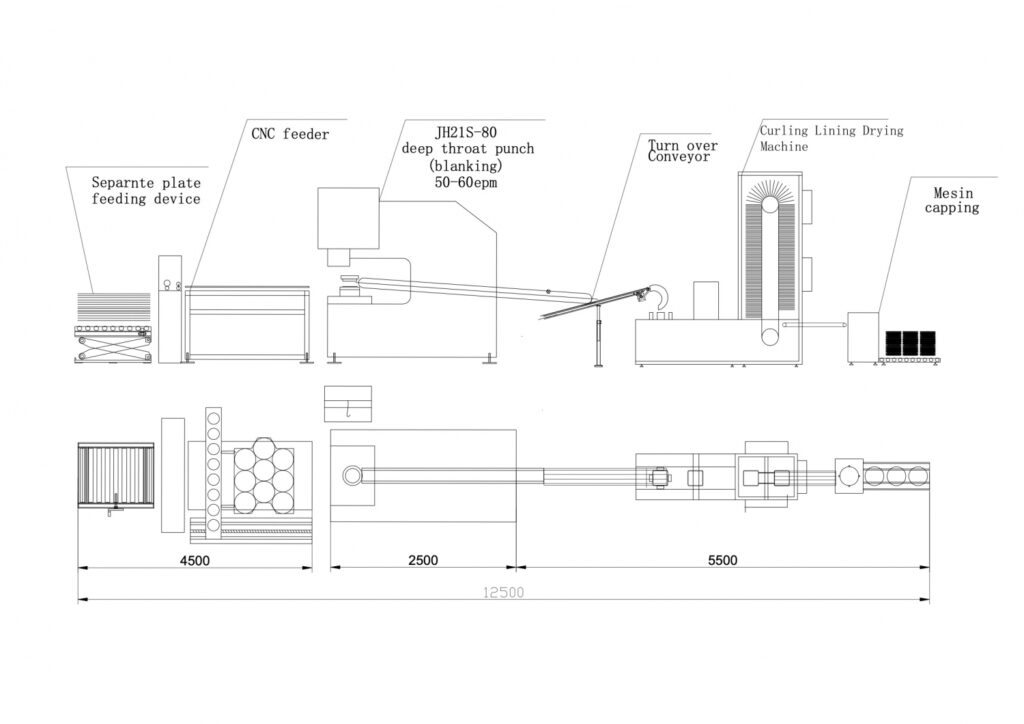

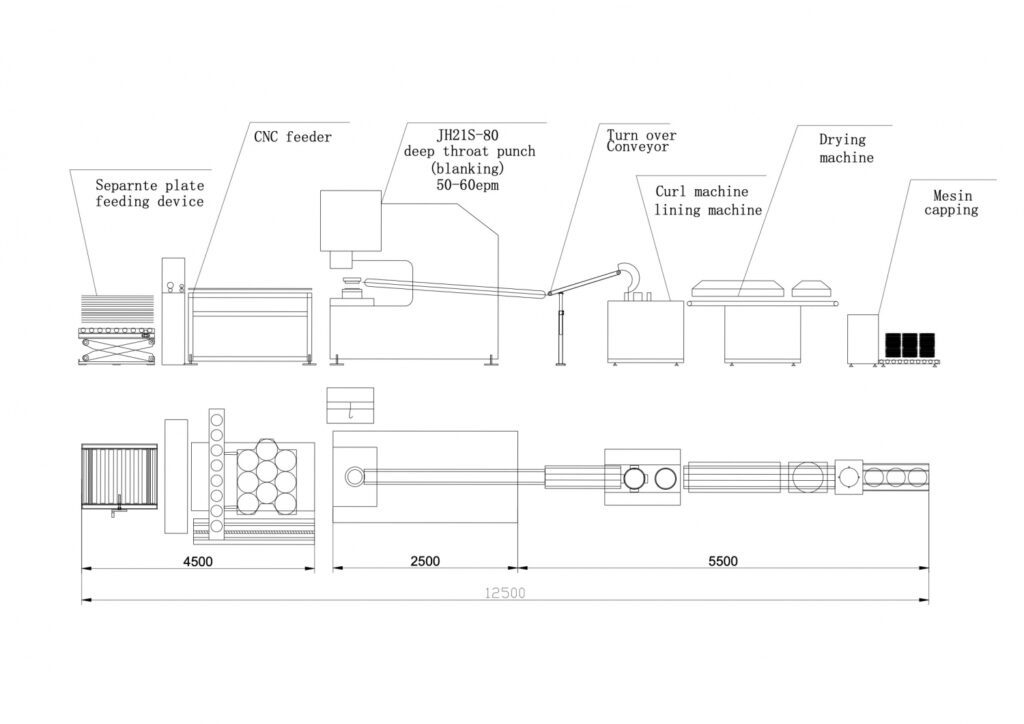

60EPM D271MM BOTTOM LID LINE FOR TIN PAIL CAN MAKING

THE LAYOUT OF THE PRODUCTION LINE