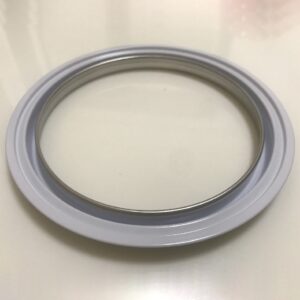

Automatic general can ring making line

Including automatic uploading machine and CNC sheet feeding system, high precision deep-throat pneumatic press for basic ring drawing, servo conveyor system, high precision progressive portal press for ring forming operations, progressive toolings, curling machine, lining machine and induction oven.