Automatic small round can production line

1. INTRODUCTION TO SMALL ROUND CAN

It is 3-pc can (mostly made of tinplate material) consisting of can body, lid and bottom. The can is round shaped. The can capacity is generally 0.5-5L, diameter 50-180mm, and height 80-320mm.

The cans are widely used for chemicals, paints, lubricant oil, etc.

2. BASIC SPECIFICATIONS AND PRODUCTION PROCESS OF AUTOMATIC SMALL ROUND CAN MAKING LINE

The production line is applicable for the automatic production of 0.5L-5L small round cans.

Can diameter range: 50-180mm

Can height range: 80-320mm

Production capacity: 55-60cpm.

Total power: about 75Kw

Floor space needed: about100㎡

Manpower required: 3-4 workers

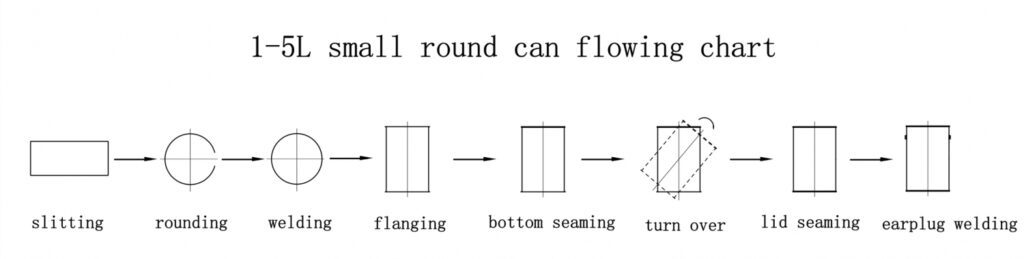

Technical workflow: body blank slitting – rounding – body welding – internal & external welding seam coating – top & bottom flanging – bottom seaming – turnover – top seaming – ear lug welding – leak testing – packing.

3. EQUIPMENT COMPOSITION OF AUTOMATIC SMALL ROUND CAN PRODUCTION LINE

Autotamtic gang slitter

| Gang slitter with automatic feeder and stacker | |

| Maximum sheet size (L*W) | 1100*1100mm |

| Minimum sheet size (L*W) | 200*400mm |

| Maximum speed | 50 sheets/min |

| Power supply | 380V/50Hz |

| Total power | 3.5Kw |

| Gross weight | 1800Kg |

| Feeder & stacker payload | 3T |

Autotamtic body welder

| General can body welding machine | |

| Welding frequency | 100-280Hz |

| Welding speed | 10m-20m/min |

| Production capacity | 60-100cans/min |

| Can diameter | Φ52-Φ176mm |

| Can height | 72-320mm |

| Tinplate thickness | 0.18-0.3mm |

| Copper wire diameter | Φ1.26-Φ1.38mm |

| Overlap | 0.4-0.8mm |

| Power supply | 3-phase 380V 50Hz |

| Installation power | 20Kw |

| Cooling water | 12-20℃, 40L/min |

| Air consumption | ≥300L/min, >0.5Mpa |

| Gross weight | 2800Kg |

| Dimension (L*W*H) | 2000*1600*1900mm |

Lacquer coating machine

| External welding seam lacquer coating machine | |

| Can diameter | Φ52-350mm |

| Can height | 50-600mm |

| Coating speed | 8-50m/min |

| Coating width | 8-18mm |

| Compressed air | 0.4Mpa/cm² |

| Input power | 380V/50Hz |

| Dimension (L*W*H) | 1800*600*1300mm |

| Gross weight | about 500Kg |

Full automatic can body combination machine

| Full automatic can body combination machine | |

| production capacity | 60cpm |

| drum body diameter range | Φ52-180mm |

| drum body height range | 80-320mm |

| thickness | ≤0.35mm |

| total power | 13.1KW |

| pneumatic system pressure: | 0.5Mpa |

| body uprighting conveyor size | 2250*230*920mm |

| the front section conveyor’s size | 2740*260*880mm |

| seaming machine size | 2200*1120*2120mm |

| the front section conveyor’s size | 2740*260*880mm |

| seaming machine size | 1320*1120*2120 |

| main machine weight | 5.5T |

Automatic Feeding Double Head Ear Welder

| Automatic Feeding Double Head Ear Welder | |

| drum body diameter range | 142-150mm |

| drum body height range | 150-210mm |

| production capacity | 50pcs/min |

| total power | 30KW |

| Lubrication system | Manual lubrication |

| Compressed air required | 0.4Mpa*10L/min |

| Dimensions(L*W*H) | 2660*1397*1790mm |

| Device Weight | 200KG |

Leak tester

| Leak tester | |

| Detected product volume range | 1-5L/5L |

| Equipment air pressure | 4-6Bar |

| Check pressure | 10-15Kpa |

| Detection accuracy | 0.17mm |

| Detection speed | 30PCS/mins/60PCS/mins |

| Device Weight | 1500KG/3800KG |

| Dimensions(L*W*H) |

L3200mmB950mm H2200mm/L3400mm B2200mmH2300mm |

| Input power | 220V50HZ/380V50HZ |

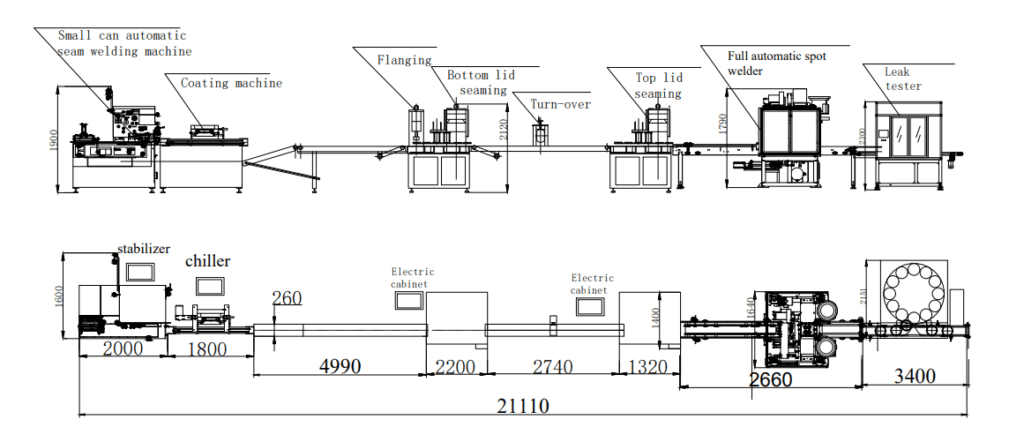

THE LAYOUT OF THE PRODUCTION LINE

TIN CAN MAKING ARTCRAFT

4. ADVANTAGES AND DISADVANTAGES OF THE FULL-AUTOMATIC PRODUCTION LINE OFSMALL ROUND CANS

Advantages: the whole production line adopts automatic computer programming control system, fully realizing the full automatic assembly line work.Only 1-2 workers are needed to complete the operation of the entire production line.The whole production line has fast production speed, high production efficiency, automatic fault detection system and low rejection rate.

Disadvantages: compared to semi-automatic production line, the initial investment capital is larger. For the start-up enterprises,It is recommended to use semi-automatic production line with less capital in.

5.COMPARISON BETWEEN DELICACY PRODUCTS AND ITS COMPETITORS

Delicacy products: the whole production line is suitable for a variety of can types in a production line factory. The cost of mold is low and the time of mold replacement is short. It only takes 1.5-2 hours to complete the replacement of all the molds. At the same time, the machine head adopts special design, which has the characteristics of low noise and high production speed,

Peer products: the whole production line only produces one can type, the mold cost is high, the time of changing the mold is long, it takes 1-3 days to complete the replacement of all the molds. The machine head adopts the old design and the production noise is large.

6.APPLICATIONINDUSTRY

This production line is applicable to the production of metal round cans for food, medicine, chemical industry, paint, cooking oil and other industries. It can also be used in the production of food cans, paint cans, edible oil cans, paint cans, milk powder cans, aerosol cans, etc.

7.APPLICABLE COUNTRIES AND REGIONS

Applicable to countries or regions where labor is difficult, unstable, or highly paid. For example: Malaysia, Indonesia, Philippines, Vietnam, Thailand, India, dubai and so on.

Applicable to countries or regions with high output and high product quality. For example: Saudi Arabia, dubai, Russia, Canada, South Korea, Turkey and so on.

8.WHY TO CHOOSE DELICACY PRODUCTS

1. Established 20 years ago, Delicacy technology is a well-known brand in the Chinese industry.

2. More than 80% of customers in China have used Delicacy products.

3. Delicacy technology has a strong technical team and professional after-sales service to provide customers with turnkey project and one-stop service.

4. Once choosing Yixin technology products, Delicacy technology will provide you with the most professional technical advice and guidance from material selection, printing and typesetting, installation, commissioning to smooth production.