Automatic big square can production line

1. INTRODUCTION TO BIG SQUARE CAN

It is 3-pc can (mostly made of tinplate material) consisting of can body, lid and bottom. The can is square shaped. The can body has embossing on all four sides. The can capacity is generally 10-20L, diagonal 300-320mm, and height 170-450mm.

The cans can be used for various products like food, chemical, paint, edible oil, lubricating oil, medicine, etc.

2. BASIC SPECIFICATIONS AND PRODUCTION PROCESS OF BIG SQUARE CAN MAKING LINE

The line is applicable for automatic production of 10-20L square cans.

Production capacity: 20-30CPM

Total power: about 90Kw

Floor space needed: about 100 square meters

Manpower required: 3-4 workers

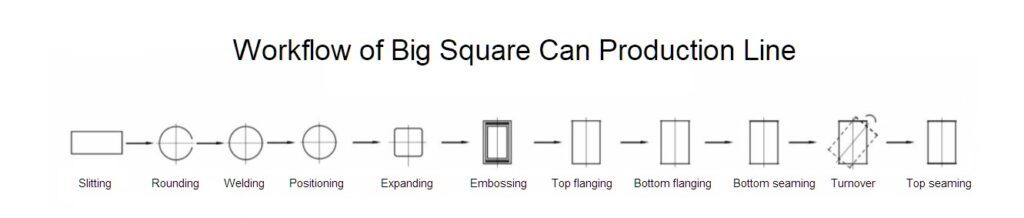

Technical workflow: body blank slitting – rounding – body welding – internal and external welding seam coating – induction curing – cooling conveyor – square expanding – embossing – top & bottom flanging – bottom seaming – turnover – top seaming – leak testing – packing.

3. EQUIPMENT COMPOSITION OF BIG SQUARE CAN PRODUCTION LINE

Automatic single slitter

| Gang slitter with automatic feeder and stacker | |

| Maximum sheet size (L*W) | 1100*1100mm |

| Minimum sheet size (L*W) | 200*400mm |

| Maximum speed | 50 sheets/min |

| Power supply | 380V/50Hz |

| Total power | 3.5Kw |

| Gross weight | 1800Kg |

| Feeder & stacker payload | 3T |

Automatic body welder

| Fully automatic can body welding machine | |

| Welding frequency | 100-280Hz |

| Welding speed | 10m-20m/min |

| Production capacity | 25-35 cans/min |

| Can diameter | Φ220-Φ300mm |

| Can height | 220-500mm |

| Tinplate thickness | 0.2-0.4mm |

| Copper wire diameter | Φ1.5-Φ1.8mm |

| Overlap | 0.6-1.0mm |

| Power supply | 3-phase 380V 50Hz |

| Installation power | 20Kw |

| Cooling water | 12-20℃, 40L/min |

| Air consumption | ≥200L/min, >0.5Mpa |

| Gross weight | about 3000Kg |

| Dimension(L*W*H) | 2200*1520*1980mm |

Powder coating machine

| Internal welding seam powder coating machine | |

| Can diameter | Φ52-Φ350mm |

| Transfer speed | 10-20m/min; 20-60/min |

| Coating width | 6-14mm |

| Powder material | Polyester epoxies |

| Installation power | 2.5Kw |

| Air consumption | ≥300L/min, >0.5Mpa |

| Input power | AC 220V, 50Hz |

| Gross weight | about 500Kg |

| Dimension(L*W*H) | 900*900*2200mm |

Lacquer coating machine

| External welding seam lacquer coating machine | |

| Can diameter | Φ52-Φ350mm |

| Can height | 50-600mm |

| Coating speed | 8-16m/min; 25-50m/min |

| Coating width | 8-18mm |

| Compressed air | 0.4Mpa/cm² |

| Input power | AC 380V/50Hz |

| Dimension (L*W*H) | 1800*600*1300mm |

| Gross weight | 500KG |

Induction oven

| Electromagnetic drying oven | |

| Hearter power | 1-2Kw |

| Production speed | above 200 cans/min |

| Can diameter | Φ45-Φ176mm |

| Can height | 45-600mm |

| Cooling water | >0.4MPa, 12-20℃, 40L/min |

| Air consumption | ≥50L/min, >0.5Mpa |

| Voltage | AC 380V/50Hz |

Automatic can body forming machine

| Fully automatic can body forming machine | |

| Production capacity | 20-30 cpm |

| Diagonal range | 300-320mm |

| Can height range | 170-450mm |

| Material thickness | ≤0.4mm |

| Total power | about 40Kw |

| Air pressure | 0.3-0.5Mpa |

| Dimension (L*W*H) | 3020*1420*3100mm |

| Gross weight | about 9T |

Leak tester

| Rotary type inline leak tester | |

| Applicable can size range | 10-20L |

| Air pressure | 4-6Bar |

| Testing pressure | 10-15Kpa |

| Detection speed | 20-30 cans/min |

| Detection accuracy | 0.15mm |

| Gross weight | about 3800Kg |

| Dimension (L*W*H) | 4000*1200*2300mm |

| Input power | 380V/50Hz |

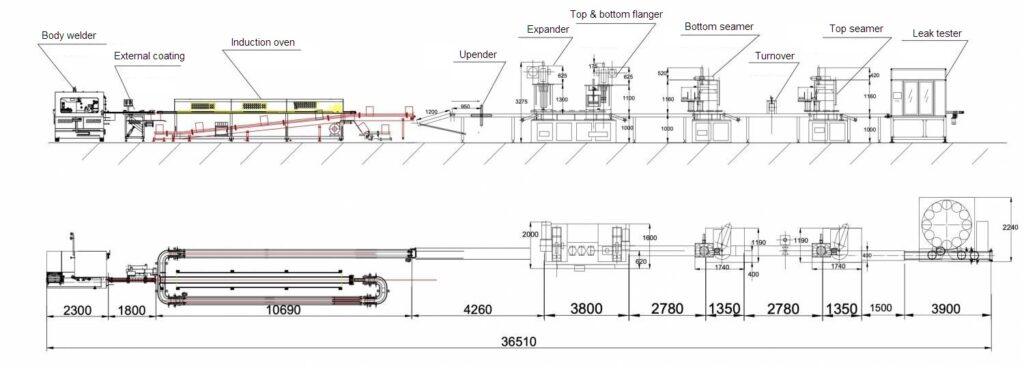

4. SKEtch layout of the production line

5. ADVANTAGES OF AUTOMATIC BIG SQUARE CAN PRODUCTION LINE

The whole production line adopts automatic computer programming control system, fully realizing the automatic forming operations. Only 3-4 workers are needed to operate the entire line. The line is with high production speed, enhanced efficiency and low waste rate.

All stations of the whole production line are made by high hardness and wear-resistant materials. The guide rails and profiles are combined with precise coordination of servo motors to ensure a fast conveying system. Meanwhile, the seaming machine head adopts special design which has the feature of low noise and high efficiency. With 8-wheel seaming machine head, the sealing quality is fast and stable.