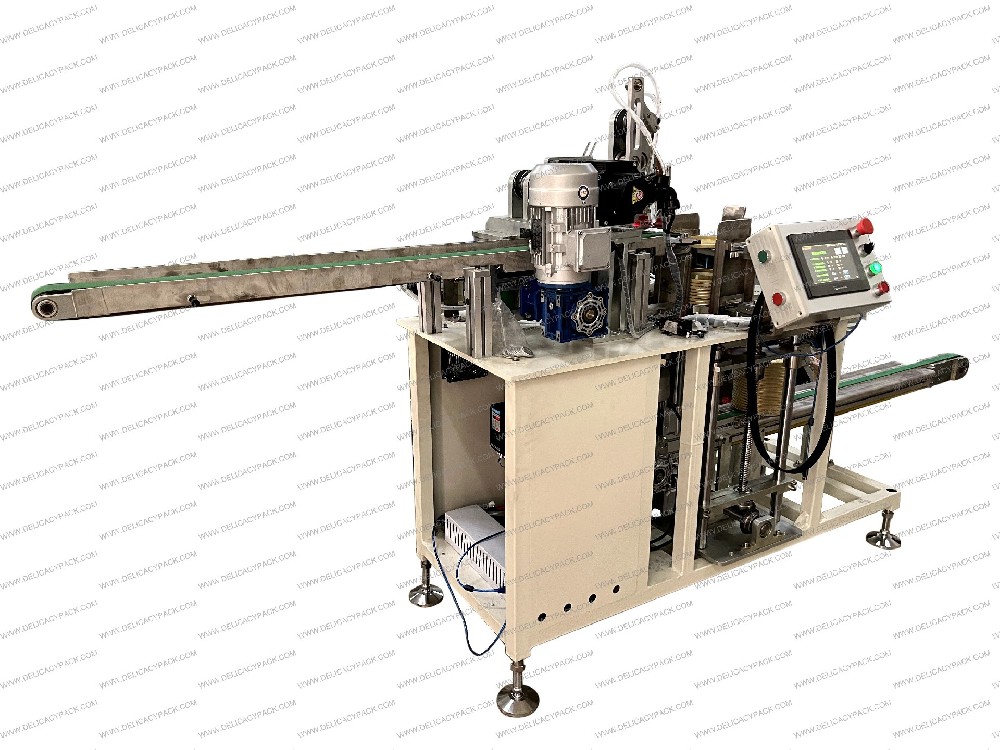

Automatic Lid Stacker For Can Making Machine

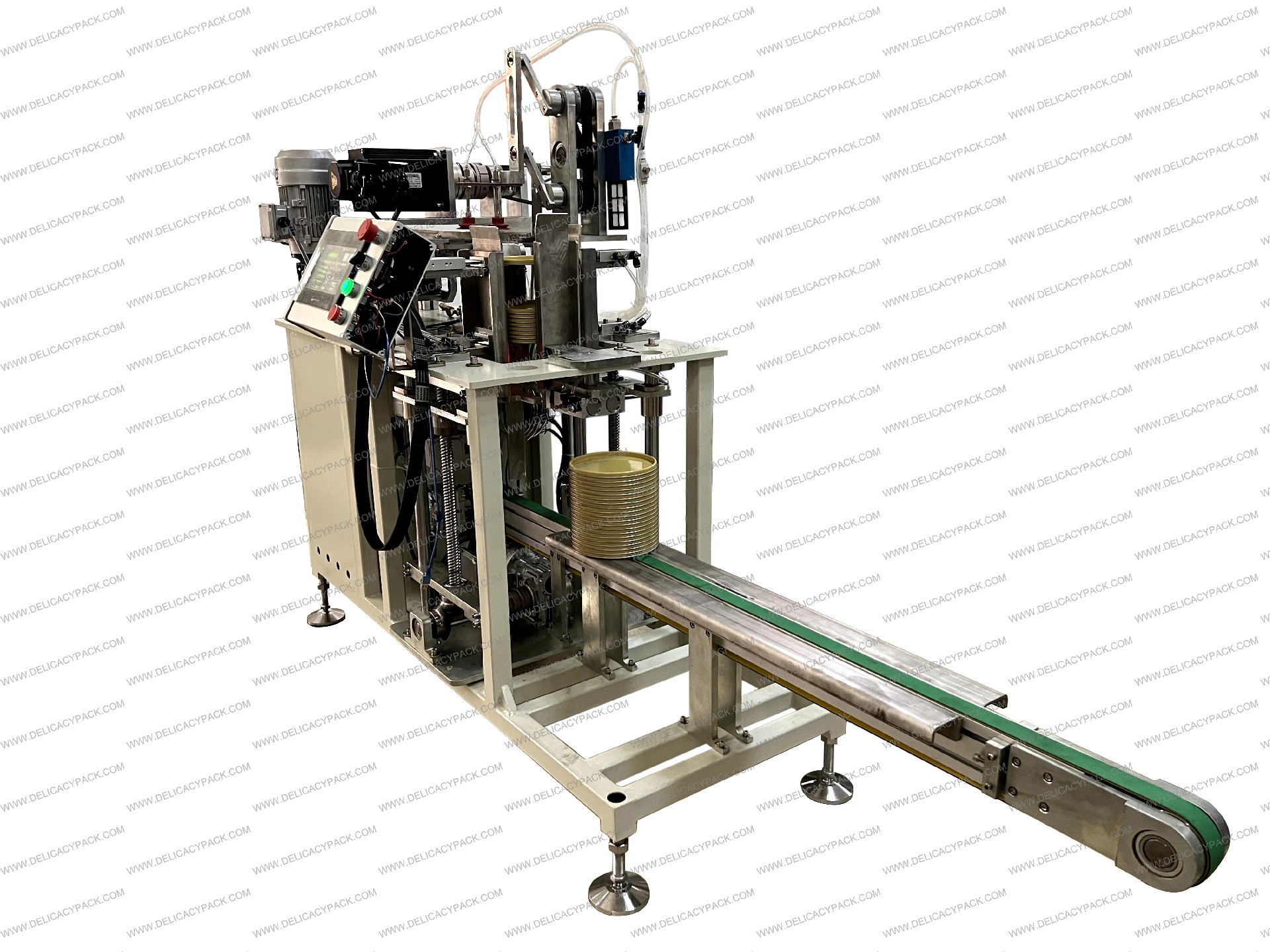

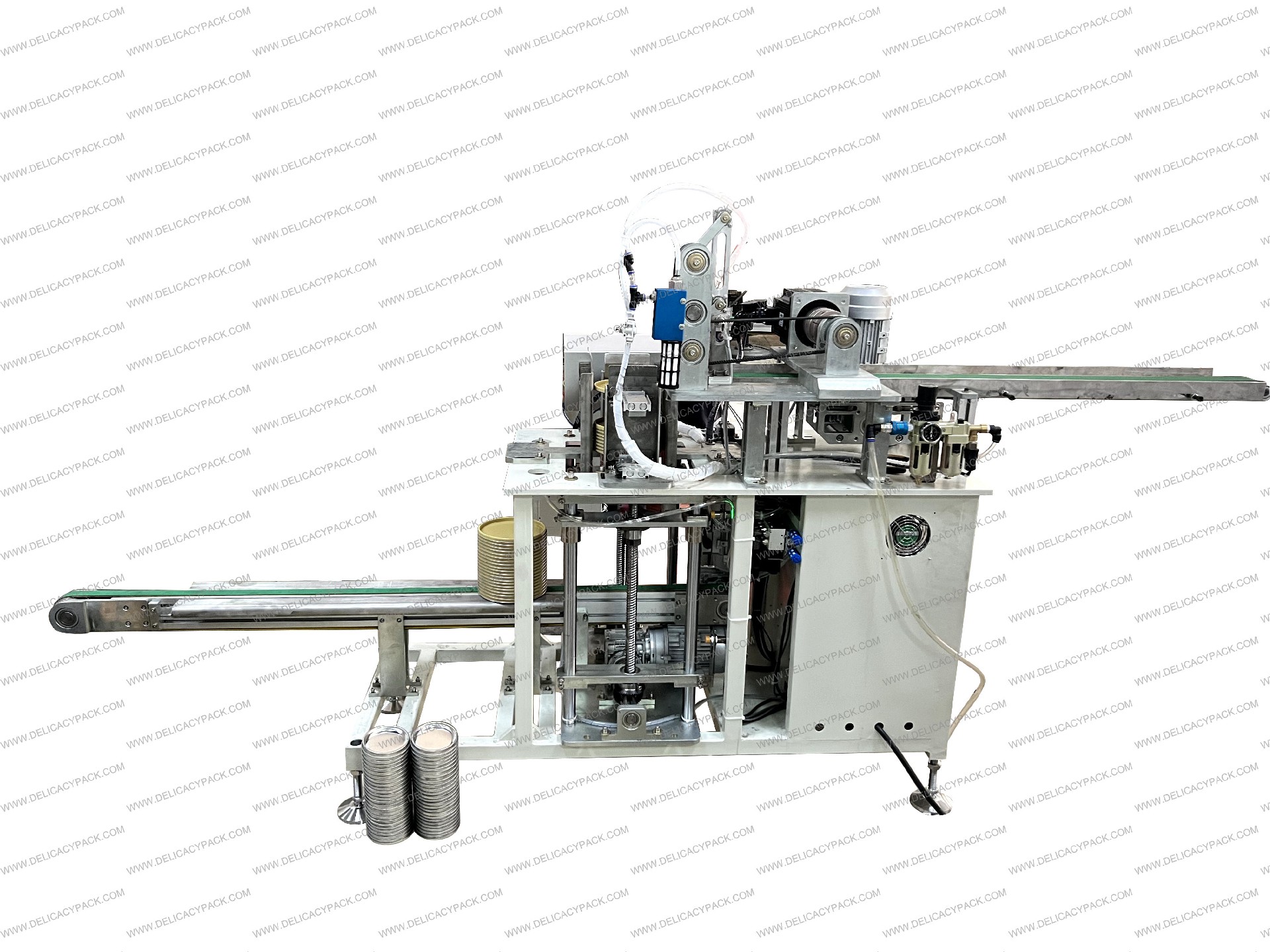

New model of lid stacker for automatic counting and stacking of round lids (smooth operation and low maintenance) Including lid inlet and outlet conveyors Adjustable for 3 different lid diameters of 105/165/175mm

New model of lid stacker for automatic counting and stacking of round lids (smooth operation and low maintenance) Including lid inlet and outlet conveyors Adjustable for 3 different lid diameters of 105/165/175mm

Production speed: 60-70EPM (adjustable for lower speed)

Total power: about 5Kw

Voltage: AC 380V 50Hz

Main electrical configurations: Pneumatic components: Airtac

PLC & inverter: Inovance

HMI: Weinview

Power switches: Keyence

Optical sensors: Panasonic

An automatic lid stacker is a type of industrial equipment used for automatically stacking lids in a neat and organized manner. The machine is commonly used in the food packaging industry for stacking various types of lids such as aluminum, plastic, and composite lids.

The automatic lid stacker operates by feeding lids into the machine through a conveyor system, which then transfers the lids to a stacking station. The machine then stacks the lids in a predetermined pattern or configuration, depending on the specific requirements of the packaging process. Once the stack is complete, the machine can either discharge the stack onto a conveyor for further processing or transfer the stack to a packaging line.

The automatic lid stacker is an essential piece of equipment in the food packaging industry, as it allows manufacturers to stack lids quickly and efficiently, reducing the need for manual labor and increasing production speed. The machine also ensures that the lids are stacked evenly and precisely, which is important for maintaining the quality and integrity of the packaging.

Overall, the automatic lid stacker is a valuable addition to any food packaging production line, helping to increase efficiency, reduce labor costs, and ensure consistent and high-quality packaging.